Eric PIRARD

Professeur Ordinaire

Ressources Minérales & Economie Circulaire

THE FOUR CHALLENGES OF A CIRCULAR ECONOMY

Energy Transition and Circular Economy

Until a few centuries ago, farmers and blacksmiths used exclusively renewable energy. Whether it was animal power, charcoal or even windmill, these energies were widely available and did not require exceptional infrastructure. At most, man used seven metals to serve needs as diverse as weapons, construction or jewellery: gold; silver; iron; tin; copper; lead; and mercury.

The industrial revolution has multiplied by a thousand the energy needs of each individual! As biomass is no longer able to keep up, man has turned to fossil biomass and since then has never extracted as much lignite, coal, gas or oil as in 2019. This frenetic consumption is challenging and inevitably raises the question of limits, whether through an analysis of remaining reserves or through the concern to limit CO2 emissions into the atmosphere. The uninterrupted growth in population and the access of more people to better material comfort only reinforce this pressing feeling of a necessary change of course.

The great opportunity for humanity is that there are still enough fossil resources to give itself time to analyse a possible energy future, whether centralised or decentralised, whether it is based on a better understanding of nuclear energy, a better knowledge of geothermal resources or a better performance of wind and photovoltaic technologies. For many engineers and energy specialists, there is in any case no need to act in haste under the threat of a climate emergency or an anti-nuclear ukase.

Our ancestors' windmill has evolved well and is now close to optimal performance thanks to a more aerodynamic design and the use of more efficient materials. The transformation of energy into electricity and, above all, the possibilities of storage make it possible to use this energy at any time and in any place. But this progress has a cost that is the unprecedented mobilization of an unprecedented quantity and diversity of raw materials. A 3 MW wind turbine typically requires 840 tons of concrete, 300 tons of steel, 5 tons of copper and 400 kg of neodymium, not to mention the control electronics, which alone mobilize most of the elements of the periodic table. But it is mainly energy storage, especially in batteries, that will require huge quantities of metals to ensure the much hoped-for energy transition. It is estimated, for example, that the 30% renewable energy target combined with a similar increase in the share of electric vehicles leads to a 400% increase in cobalt requirements by 2030, not to mention lithium, nickel, copper or graphite... There will therefore be no energy transition without a more thorough exploration of our subsoil and a more intensive exploitation of its resources! While such announced “extractivism” may frighten many, it is still excellent news for future generations of geologists and geo-engineers. It could also be excellent news for sustainable development if, and only if (!), these metals feed an insatiable society that is concerned about a more circular economy.

The circular economy of metals is an interesting paradigm for reflecting on sustainable development. But it is only a paradigm and for it to become a reality it is essential to address four major challenges by putting in place the necessary technologies, standards and economic rules.

Challenge number 1 : FEED THE LOOP

The growth in needs clearly shows that a lot of mineral and metal resources will still have to be exploited to feed the loop. Today we use in abundance metals that were previously useless: germanium, which is essential for our optical fibres, indium for our touch screens and lithium for our batteries are just a few examples.

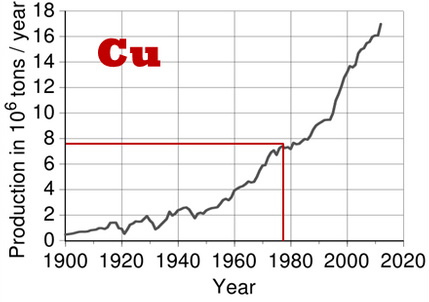

Recycling can of course help to reduce the extractive invoice, but above all, the resilience of metals in the anthropogenic cycle must be taken into account. It is estimated, for example, that the average lifetime of copper is about 40 years. Thus, even if we were able to collect it perfectly and recycle it without losing anything, we would have at our disposal at best the equivalent of the mining production of forty years ago, which is exactly half of today's needs!

Evolution of world copper consumption since 1900 according to USGS data.

Copper consumption has doubled over the past forty years.

Challenge number 2 : BUILD THE LOOP

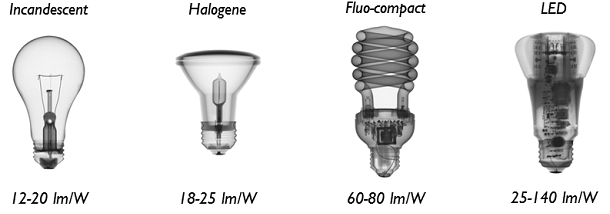

Technological progress has been the driving force of humanity since the dawn of time, it has made it possible to free oneself from the most enslaving tasks, to increase the labour force tenfold and ... to win wars. The very idea of technological progress is closely linked to the improvement of our tools in terms of greater functional efficiency or lower energy consumption. The case of the automobile is emblematic in this respect, but other technologies such as lighting show us even better that there is still a long way to go. From the point of view of energy efficiency alone, the replacement of our incandescent bulbs with diodes is indisputable since it reduces consumption by 90%! On the other hand, the mobilization of metal resources and their complex microelectronic assembly raises questions about the availability of these same resources for future generations.

Building the loop of the circular economy now requires us to design our products as stocks of materials for future generations. They are the urban mine of tomorrow and, as such, they must be easier to exploit than so-called primary ores. This is only possible on the express condition that these products are easily dismantled and recyclable. We must now think of them in terms of design for dismantling / design for recycling in order to optimize the entire production loop.

The technological evolution of lighting technology over the last few decades is indisputable in terms of functionality, but questionable in terms of the necessary metal resources and the non-recyclability of the products.

Challenge number 3 : SLOW DOWN THE LOOP

The establishment of a more circular economy is not just a matter for engineers or geologists. It will only be really relevant if we slow down the consumption loop. Whether the Baron Bic likes it or not, the very idea of throwing away a ballpoint pen after use is totally incongruous. We must find a relationship with the object that encourages us to preserve, repair and reuse it as much as possible. The poorest economies offer many exemplary lessons in this regard. Zero waste is not a slogan but a reality.

In this perspective, it is clear that new business models must be supported, whether they are inspired by the economics of functionality or whether they encourage manufacturers to grant extended warranties on their products. We will legitimately have to worry about the brake on technological innovation that this could induce, but there must surely be a reasonable path between stagnation and futile progress. However, it will require a Copernican revolution in the culture of consumerism and excessive marketing.

Challenge number 4 : CLOSE THE LOOP

Even if everything must be done to delay this deadline, there comes a time when a product is legitimately at the end of its life and, having lost all functionality, its residual value is that of the materials that form it. This is where recycling comes in, i.e. the technical operation of separating and preparing these materials for a new cycle. A very telling analogy of recycling is the Plasticine modelling clay. If we are not careful, at the end of the day, our materials mix into a ball of infamous colour and there is no future. If we are meticulous it is possible to separate the basic colours and bring new products back to life. It is also necessary that the recycled materials find a buyer and that they are ready to put a price that covers the cost of recycling. The reality today is that all this is only possible thanks to sustained subsidization because there is still too much mistrust of the performance of recycled raw materials or the price of primary metals is far too low!

Innovations such as smart sorting robotics and artificial intelligence techniques, offer interesting prospects for improving recycling performance, but it is important to always keep in mind that the most efficient recycling process rarely exceeds 95%. In other words, after 15 cycles, only half of the initial resource may remain, the rest being dissipated in final waste!

Eric PIRARD, July 3rd 2019